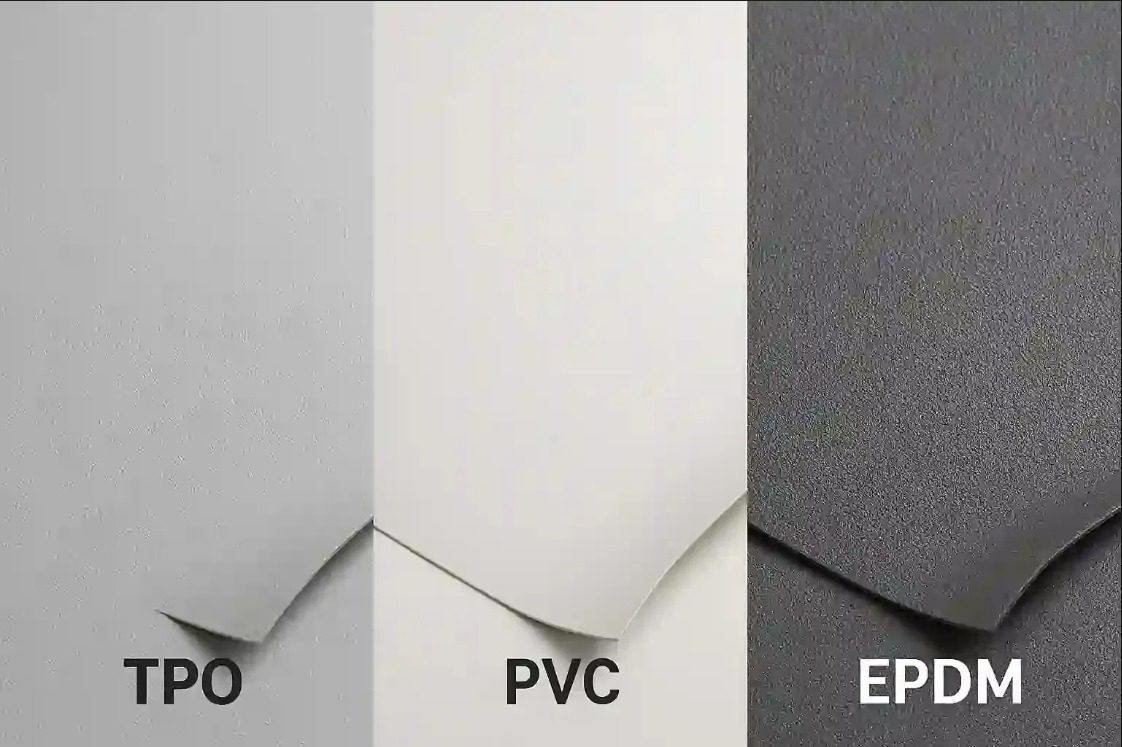

Difference Between TPO vs PVC vs EPDM Roofing Membranes?

Choosing the right membrane for your commercial roof can save thousands in repairs and energy costs. With options like TPO, PVC, and EPDM, Texas building owners often struggle to compare performance, lifespan, and installation complexity. In this guide, you’ll learn the key differences between these popular roofing membranes, understand the pros and cons, and discover which commercial flat roof material works best for your building. G&M Roofing Services provides expert guidance and installation, ensuring your business has a long-lasting, energy-efficient roof.

What Are Membrane Roofing Systems Used for in Commercial Buildings?

Membrane roofing systems are designed for flat or low-slope commercial roofs, providing a waterproof barrier that protects buildings from rain, wind, and UV damage.

They help extend roof life, improve energy efficiency, and reduce maintenance costs.

Business owners in Texas rely on these systems to protect assets while keeping long-term operational costs low.

How Do TPO, PVC, and EPDM Differ in Performance?

How Durability and Lifespan Compare Across Membranes

TPO vs PVC vs EPDM Roofing Membranes each have different lifespans and durability features.

- TPO Roofing: 15–20 years average lifespan, resistant to UV and heat.

- PVC Roofing: 20–25 years, highly chemical-resistant and durable.

- EPDM Rubber Roof: 25–30 years, extremely flexible but less puncture-resistant than PVC.

Durability varies based on maintenance, climate, and exposure to the Texas sun and storms.

What Makes Installation More Complex for Certain Systems

Installing TPO vs PVC vs EPDM Roofing Membranes requires different techniques. TPO and PVC need heat-welded seams for proper waterproofing, requiring skilled installers. EPDM is simpler to install with adhesive or mechanically fastened sheets. Complex installation affects labor costs and roof longevity.

How Energy Efficiency Changes Between TPO and PVC

TPO reflects UV light and reduces cooling costs, but can shrink in extreme heat. PVC offers superior reflectivity and chemical resistance, keeping energy bills lower. EPDM is dark by default, which can increase cooling costs unless coated with reflective paint.

What Are the Best Use Cases for Each Membrane Roof Type?

- TPO Roofing: Ideal for large warehouses and office buildings. Works well for moderate budgets.

- PVC Roofing: Best for chemical plants, restaurants, or rooftops with grease or oil exposure. Durable and long-lasting.

- EPDM Rubber Roof: Perfect for small to medium commercial buildings. Offers flexibility and a long lifespan.

Which Roofing Membrane Performs Best in Texas Heat?

PVC generally performs best under intense Texas sun, offering long-term durability, superior chemical resistance, and energy efficiency. TPO is also effective but may shrink over time, while EPDM requires reflective coatings to optimize heat performance.

Cost & Material Considerations for Membrane Roofing

Material choice impacts cost, maintenance, and longevity.

- TPO: Affordable initial cost, moderate lifespan.

- PVC: Higher upfront cost, long-term durability.

- EPDM: Moderate cost, longest lifespan if maintained properly.

Labor, roof size, and complexity of installation will also affect total project costs. G&M Roofing Services provides free inspections and quotes to help businesses select the right membrane roofing system.

Challenges with Membrane Roofing

- Seam and Shrinkage Issues

Over time, membrane seams, especially adhesive ones in EPDM, can loosen or shrink, creating leak risks if not inspected regularly.

- Ponding Water Risks

Flat membrane roofs can experience ponding water after storms, which stresses seams and materials and may lead to leaks or membrane deterioration. - Installation Quality Matters

Improperly installed TPO or PVC roofs can suffer from weak seams, poor drainage, and early failure, making professional installation crucial for performance. - Material Sensitivity to Climate

EPDM can shrink or age differently in intense heat, while TPO and PVC may degrade under prolonged high temperatures without reflective surfaces, so climate affects long‑term performance.

Meet G&M Roofing Services: Trusted Roofing Experts in Texas

G&M Roofing Services is a fully licensed and trusted roofing contractor based in Plano, TX, proudly serving residential and commercial clients across Texas. We bring years of real industry experience and a strong reputation for delivering durable, high-performance roofing systems.

- Licensed, insured, and experienced across hundreds of Texas roofs.

- Experts in durable, energy-efficient roofing systems.

- Full services: repair, replacement, inspection, and maintenance.

- Serving homes, offices, warehouses, and commercial properties.

- Honest, transparent, customer-first approach.

- Roofs built to withstand Texas heat and storms.

Conclusion

Choosing the right TPO vs PVC vs EPDM Roofing Membranes, whether TPO, PVC, or EPDM, makes a big difference in durability, energy costs, and long‑term performance for commercial buildings. Each membrane type has unique strengths, from chemical resistance to weather performance, so understanding the differences helps you make the right choice. Proper installation and regular inspections are key to maximizing the lifespan of any TPO vs PVC vs EPDM Roofing Membranes system. Schedule a professional consultation so you can select the best roof type for your property and avoid costly repairs down the road.

Stay updated on our services and special offers. Connect with us on LinkedIn, Instagram, and Google My Business.

Contact us today to schedule your inspection or get a free quote.

FAQs

- What is the main difference between TPO, PVC, and EPDM roofing membranes?

TPO is thermoplastic and offers good UV resistance and energy efficiency, PVC is highly chemical‑resistant with a long lifespan, and EPDM is a rubber membrane known for flexibility and weather resilience. The choice depends on climate, building use, and maintenance preferences. - Which membrane lasts the longest?

PVC typically has the longest lifespan of the three, often 30+ years with good upkeep, while EPDM and TPO usually last around 20–30 years, depending on conditions. Longevity varies with maintenance and installation quality. - Are these roofing membranes energy efficient?

TPO and PVC are usually white and highly reflective, reducing rooftop heat and cutting cooling costs. EPDM is often black and absorbs heat, which may increase cooling needs unless it’s coated for reflectivity. - Is installation difficult for these membranes?

TPO and PVC require heat‑welded seams that need skilled installers, while EPDM uses adhesive or mechanical fastening and can be simpler to install. Professional installation improves waterproofing and longevity. - Which membrane is best for chemical exposure areas?

PVC stands out with excellent chemical and grease resistance, making it ideal for restaurants, labs, or industrial facilities. TPO and EPDM are less resistant to heavy chemical environments by comparison.